Results

Decentralized conversion technologies to an energy carrier

Fast pyrolysis to biosyncrude

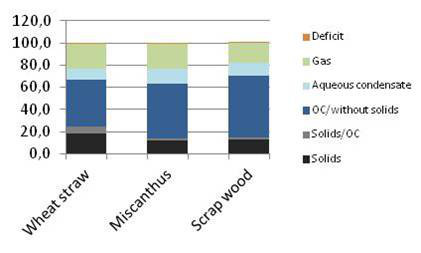

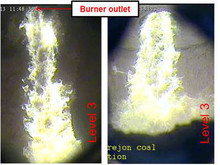

At the Karlsruhe Institute of Technology (KIT) scientists applied fast pyrolysis to convert straw and other residues into a biosyncrude, a mixture of FP oil and coal. The intermediate energy carrier biosyncrude FP is suitable for gasification and subsequently following transportation fuel production according to the bioliq concept. Beyond this reference pathway, conditioning procedures were explored allowing for flexible use of pyrolysis products for alternative energetic use, generating added value and helping to facilitate technical and market implementation. For that purpose separate combustion tests for char and biooil are conducted at University Stuttgart and the German Aerospace Center (DLR) in Stuttgart, respectively.

Fast pyrolysis yields of different types of biomass.

Â

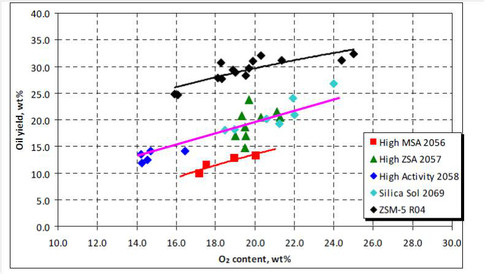

Catalytic pyrolysis to CPO

CPERI/CERTH applied the catalytic pyrolysis process using wood chips aiming at the production of catalytic bio-oil (CPO) that has a maximum product yield related to the biomass feed capacity with minimum oxygen content. This bioenergy carrier can be used for the production of transportation fuels in an existing refinery infrastructure. The process optimization work aimed at the improvement of catalytic materials, feedstock types and process operating conditions. The entire work was carried out in collaboration with the BioBoost partners GRACE and Neste. GRACE performed the catalyst synthesis and catalyst scale up while CPERI carried out the catalyst pre-screening and the process optimization studies on pilot scale. Neste investigated upgrading options of CP oils (CPO) delivered by CPERI.

Sample of catalytic pyrolysis oil.

Â

Â

Catalytic pyrolysis to CPO

Several litre of CP oils were produced from the various catalysts and feedstocks and were fully characterized using routine and advanced characterization methods like e. g. 2D GC-TOF-MS. The CP oils were given to NESTE for refinery application and to other BioBoost partners for further downstream upgrading processes. The characterization studies showed that CP oil produced from this pathway has significant advances regarding its much lower oxygen and less organic acid content and the higher stability while it is also a source of useful chemicals like phenols. In terms of stability, CP oil shows minimum corrosiveness, according to the copper corrosion test, even after 27 months storage. The high heating value and the total acid number value were stable but the aqueous content showed little variation, due to gradual phase separation over time. The important properties for storage and transport are density and viscosity, as they determine the pumping process.

Hydrothermal carbonisation to Biocoal

Hydrothermal carbonization (HTC), carried out at more moderate temperatures around 200 °C and corresponding pressures around 10 bar, leads to biocoal as the main product. In the BioBoost project HTC biocoal has been considered as combustion fuel for heat and power production. First, screening experiments on hydrothermal carbonisation with batch micro-autoclaves have been performed at KIT to find optimum conversion conditions. Important findings are that the nature of the feedstock as well as pre-heating has an important impact on the reaction. This and other observations lead to the development of a kinetic model. This model is able to describe the reaction kinetics of different biomass feedstocks. The screening of biomass conversion and the kinetic model lead to optimized operation of the HTC process at AVACO2. Here, experiments with brewery spent grains (BSG) and organic municipal waste (OMW) in a bench scale and industry size reactor were performed.

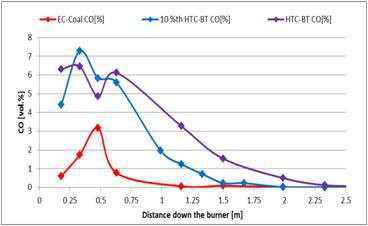

HTC Biocoal combustion

Pulverized bio-coal from HTC and FP was tested for combustion by co-firing with conventional coal as well as by mono-firing by UOS in laboratory and pilot scale pulverized fuel combustion facility with 20 and 500 kW, respectively. The tests were focused on the investigation and evaluation of combustion performance, stability and emission behaviour and compared to the hard coal (mono) firing case.

Â

CO concentration profile down the burner along the furnace center during coal (mono-firing), 10 % SBG (co-firing) and OMW biocoal (mono-firing).

| Dateityp | Datei | Dateigröße | Download |

|---|---|---|---|

| Del 2.1 Feedstock selection | 816 KB | Download | |

| Del 2.2 Protocol MS2 Product range from fast and catalytic pyrolysis and hydrothermal carbonization | 150 KB | Download | |

| Del 2.6 Final Report WP 2 | 2329 KB | Download |

Achievements

Biosyncrude production optimized toward high sedimentation stability, energy content, minimum energy consumption for storage, transportation and feeding to a gasifier.

Fast pyrolysis products meet gasification specifications.

Recomendations

Large scale testing in bioliq plant required.

Â

Achievements

Catalytic pyrolysis oil is a very stable energy carrier that can be stored and handled in a similar way to conventional fuels.

Catalytic pyrolysis oil is suitable for industrial handling.

Recomendations

Testing of larger quantities from

pilot or demo plant operation.

Â

Achievements

Co-firing with coal is technical feasible, in some cases also mono-firing is possible.

Recomendation

As different combustion behavior has impact on burner and boiler design further testing is required.

Â

Â